Product recommendation

High-Efficiency Starch Separator Maximizes Yield and Purity in Industrial Starch Processing

In the starch production industry, separating starch from gluten, fiber, and other unwanted components is a critical step in ensuring high product purity and yield. A starch separator plays an essential role in this process, especially in large-scale operations where performance, reliability, and efficiency are vital.

At SOHO HONRY, we specialize in manufacturing high-quality industrial starch processing equipment that delivers exceptional performance. Our advanced starch separator is engineered for high efficiency, low vibration, and extended operational life—making it ideal for processing starch from corn, cassava, potatoes, and other agricultural sources.

Why a Starch Separator Is Essential in Industrial Starch Production

A tarch separator functions by using centrifugal force to extract starch from a mixture of gluten and other components. This centrifugal separator for starch and gluten operates at high speed, allowing the starch to separate from protein and impurities efficiently. This high-speed rotation dramatically improves separation precision while reducing the processing time per batch.

In modern starch processing lines, a high-efficiency starch separation machine is indispensable for:

Pre-concentration of starch

Separation of starch and gluten

Gluten (protein) concentration

Clarification of process water

Our continuous starch and protein separator is specifically designed to handle these steps with maximum effectiveness.

Key Technical Features of the SOHO HONRY Starch Separator

Large-capacity stainless steel starch separator: Equipped with a large-diameter drum and a wide-area disk, the machine offers superior throughput without compromising on separation quality.

Automatic starch separator with top-suspension drive: The top-suspension system provides enhanced rotational stability, significantly reducing wear on the main shaft and bearings, and extending service life.

Built-in automatic lubrication system: Monitors and controls oil flow automatically, keeping essential parts in optimal condition and reducing manual maintenance.

Large nozzle design: Minimizes clogging, enhances feed volume, and ensures consistent, continuous production—perfect for demanding industrial applications.

Hydraulic lifting system: Allows for fast and safe access to the drum for cleaning and nozzle replacement, minimizing downtime.

Corrosion-resistant stainless steel construction: Ensures long-term stability, hygiene, and reliability—even in high-moisture or acidic environments.

Inner circulation system: Stabilizes the separation process and improves control accuracy during continuous operation.

Wide processing range: Can handle raw materials with varying concentrations without internal adjustment—ideal for facilities working with different crop types.

Easy operation and training: Designed to be user-friendly, even for first-time operators, reducing training costs and human error.

These features combine to make the SOHO HONRY starch separator a powerful and efficient solution for modern industrial starch processing equipment setups.

Application Across Diverse Starch Processing Industries

Whether you're operating a corn starch plant or a cassava-based facility, a high-efficiency starch separator is key to your production success. Our machine is widely used in:

Starch processing

Agro-processing enterprises

Food additive production

Bio-refinery and biochemical engineering

Potato and cassava starch manufacturing

Our centrifugal separator for starch and gluten ensures you achieve high-quality end products that meet international standards.

Advantages of the SOHO HONRY Starch Separator

Using a high-efficiency starch separation machine offers multiple advantages:

Higher starch yield from every production cycle

Improved gluten concentration for food-grade or industrial uses

Reduced downtime and maintenance costs

Consistent batch quality even at high throughput

Scalable performance for small plants or large industrial operations

The automatic starch separator with top-suspension drive ensures stability and precision over long working hours. Combined with our smart design and high-end materials, our large-capacity stainless steel starch separator stands as a benchmark in the industry.

Why Choose SOHO HONRY?

SOHO HONRY is a professional manufacturer of mechanical equipment, serving industries ranging from food and beverage to agriculture and environmental solutions. We don't just specialize in one category—we offer a wide range of machines, each designed with a commitment to reliability and performance.

Our industrial starch processing equipment reflects decades of engineering experience. We partner with top-tier component suppliers including Siemens, Mitsubishi, Schneider, and Omron to ensure stable, long-lasting performance. Every starch separator we produce is tested rigorously to meet both domestic and international standards.

Our after-sales service includes installation guidance, technical support, and spare parts availability to ensure your operation runs smoothly.

Why SOHO HONRY?

SOHO HONRY is a trusted manufacturer of industrial processing equipment with a broad portfolio covering food, beverage and chemical industries. We design and produce machinery with a focus on quality, automation, and durability. Our starch separator exemplifies this mission — offering cutting-edge performance backed by dependable engineering.

Choosing SOHO HONRY means choosing durability, precision, and value. As a trusted manufacturer of starch separator machines and other industrial equipment, we understand your need for efficient, high-performing solutions. Our products offer:

Proven quality from a reliable Chinese manufacturer

Advanced automation and safety features

Flexible customization options

Competitive pricing with global support

Whether you're upgrading your production line or building a new starch processing facility, the SOHO HONRY high-efficiency starch separation machine is your smart investment for better productivity and higher profitability.

Please visit product page for more information

-

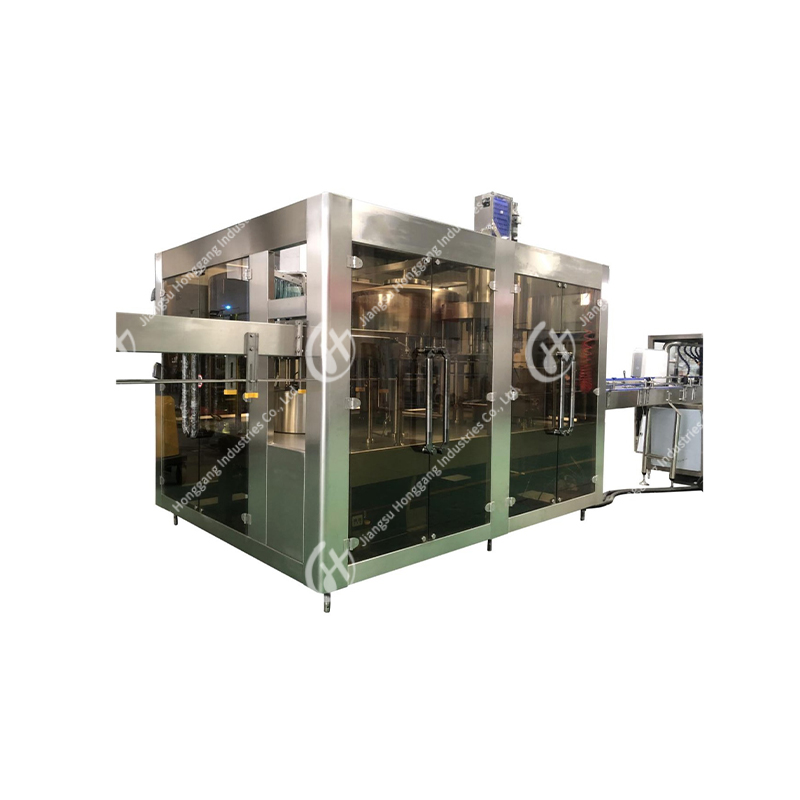

Starch Separator

People will crash and separate the mature crops depend on their physical properties, then obtain starch. So the starch separator is the key in the process of starch extraction. In the starch separation process, the separator rotates in high speed then creates the centrifugal force, so the separation efficiency is improved. At the same time maximize the production efficiency. We devote ourselves to make Hongrui wuxi branch starch separator to the most professional and efficient in starch processing industry, it collects all the advantages of various separator such as small vibration, large capacity, stable running and so on. If s mainly used in pre-concentration starch, separation of starch and gluten, concentration of gluten (protein), clarify of process water in the after step and so on.

More