Product recommendation

Oil separators are vital components in the functioning of various mechanical systems, especially in engines. They play a significant role in improving engine performance, enhancing fuel efficiency, and extending the engine's life. Understanding how oil separators work, their types, and maintenance tips can help users maximize their benefits. This article will explore the operation of oil separators, their benefits, types, maintenance, and why selecting a high-quality oil separator from a trusted company like JIANGSU SOHO HONRY WUXI CO., LTD. is crucial.

Understanding the Function of an Oil Separator

The primary function of an oil separator is to remove excess oil and contaminants from air or fluids circulating through an engine. In internal combustion engines, blow-by gases (combustion gases that escape past the piston rings into the crankcase) accumulate with oil mist, which can cause carbon buildup and decrease engine efficiency. The oil separator's role is to capture these contaminants before they can be reintroduced into the engine or released into the atmosphere.

For turbocharged applications or high-performance engines, oil mist can increase significantly. If not filtered out, it can cause carbon buildup on engine components such as piston rings and cylinder walls, leading to reduced performance. The oil separator addresses this by capturing oil vapors, mist, and other contaminants, ensuring that only clean air or gases exit the system. Additionally, oil separators help maintain optimal fuel efficiency, reducing unnecessary wear on internal engine components.

Oil separators also reduce harmful emissions by preventing oil vapors from being released into the environment. By catching oil mist and vapor, they help engines meet environmental standards and reduce their overall impact on air quality. As such, oil separators are a key tool in both improving engine longevity and addressing environmental concerns.

How an Oil Separator Works

An oil separator works by separating oil mist, vapors, and blow-by gases from the air circulating in the engine's crankcase ventilation system. Here's how it operates step-by-step:

Crankcase Ventilation: When an engine operates, combustion gases (blow-by gases) leak past the piston rings into the crankcase. These gases often contain oil mist and other contaminants. The oil separator is part of the crankcase ventilation system, which directs these gases toward the separator.

Separation Process: Inside the oil separator, the blow-by gases pass through specialized filters, mesh, or centrifugal chambers. These components create turbulence or use centrifugal force to separate the oil mist from the gases. Since oil particles are heavier than air, they fall into a collection chamber, leaving clean air or gases to exit the separator.

Oil Recycling: The separated oil is directed back into the engine’s lubrication system, allowing the oil to be reused. This closed-loop system minimizes oil waste, reducing the need for frequent oil changes and ensuring that the oil remains clean and free of contaminants.

Emissions Control: By trapping oil mist and vapor, the oil separator reduces the release of hydrocarbons into the atmosphere, which helps engines meet emissions regulations. This reduction in emissions plays a vital role in improving air quality and minimizing environmental impact.

For industrial applications, oil-water separators serve a similar purpose by removing oil from water. These systems are commonly used in wastewater treatment and hydraulic systems, ensuring oil contamination is prevented and allowing for safe disposal or recycling of water.

Benefits of Using an Oil Separator

Oil separators offer numerous benefits that go beyond just improving engine performance. They are essential for maintaining a clean engine, reducing wear, and preventing costly repairs. Below are the key benefits of using an oil separator:

Benefit

Description

Improved Engine Performance | Oil separators help to prevent carbon buildup and contamination in engine components, resulting in smoother operation, better acceleration, and improved fuel efficiency. |

Extended Engine Life | By reducing the strain on internal components, such as piston rings and cylinder walls, oil separators help to extend the life of the engine and reduce wear. |

Reduced Emissions | Oil separators help reduce the number of hydrocarbons released into the environment, contributing to cleaner air and helping engines comply with environmental standards. |

Cost Savings | By minimizing oil waste and reducing engine wear, oil separators can help reduce maintenance costs, including fewer oil changes and repairs. |

Better Fuel Efficiency | Engines with clean, well-maintained components run more efficiently, resulting in improved fuel economy. |

Environmental Benefits | By capturing harmful oil mist and vapors, oil separators reduce the environmental impact of engine operations, contributing to sustainable practices. |

Types of Oil Separators

There are several types of oil separators, each designed to meet the specific needs of different engine systems or industrial applications. Below are some of the most common types:

Catch Cans: These standalone devices are typically used in automotive applications, especially in high-performance engines. They capture oil mist and vapors from the crankcase ventilation system. A catch can collects the oil mist, which can then be drained or recycled.

Oil Mist Separators: These separators are designed to handle high levels of oil mist found in turbocharged engines or high-performance applications. They use specialized filters or centrifugal force to capture oil particles from the blow-by gases.

Oil-Water Separators: Used in industrial settings, oil-water separators are designed to separate oil from water in wastewater treatment or hydraulic systems. These separators employ gravity or coalescing filters to capture and remove oil, preventing contamination.

Integrated Oil Separators: Some engines come with built-in oil separators as part of their crankcase ventilation or air intake systems. These separators handle moderate oil mist and vapor levels, reducing the need for aftermarket components.

High-Performance Oil Separators: For engines that generate extreme levels of blow-by gases or operate under high-performance conditions, specialized oil separators are necessary. These separators offer superior filtration and oil mist separation, making them ideal for racing engines or high-powered vehicles.

Maintaining Your Oil Separator

Proper maintenance of your oil separator ensures that it continues functioning efficiently and effectively. Regular checks and cleaning can prevent clogs and blockages, extend the separator's lifespan, and optimize engine performance. Here are a few maintenance tips:

Regular Cleaning and Checking for Blockages: Over time, oil separators can accumulate contaminants. It is essential to regularly inspect and clean the separator to prevent clogs and ensure optimal performance.

Replacing Filters: If your oil separator uses filters to catch contaminants, they may become clogged over time. Check the filters regularly and replace them according to the manufacturer's recommendations.

Inspecting for Leaks: Leaks around the separator or its connections can lead to oil loss and contamination. Ensure the separator is sealed tightly and check for any signs of leaks.

Draining Collected Oil: If your separator has a reservoir or collection chamber, periodically drain the accumulated oil to prevent overflow and ensure the system works efficiently.

Monitoring Engine Performance: If you notice a drop in engine performance, it could indicate that the oil separator needs attention. Keep an eye out for issues like decreased fuel efficiency, increased emissions, or strange engine behavior.

Choose the Highest-Quality Oil Separator from HGindustries

Selecting a high-quality oil separator is crucial for maintaining optimal engine performance. HGindustries, a leader in providing industrial solutions, offers top-of-the-line oil separators designed for high-performance applications. Known for their reliable products and quality service, HGindustries provides oil separators that help extend engine life, reduce emissions, and enhance fuel efficiency. For more information about their oil separator products, visit the HGindustries Oil Separator Products.

Additionally, HGindustries has a history of delivering quality solutions to its clients worldwide. As a trusted company that innovates and evolves within the industry, they offer not only oil separators but also a wide range of products designed to enhance performance and meet the needs of various industrial applications.

Explore their case studies and success stories through their Case Studies, or contact HGindustries directly for further inquiries at Contact HGindustries.

Conclusion

Oil separators are indispensable components in maintaining clean, efficient, and long-lasting engines. By filtering out harmful oil mist, blow-by gases, and contaminants, they improve engine performance, reduce emissions, and extend the lifespan of engine components. Whether for high-performance vehicles, industrial applications, or everyday engines, using a reliable oil separator ensures optimal functionality and environmental benefits.

For the best results, always choose a high-quality oil separator from reputable companies like HGindustries. Their experience, innovation, and commitment to quality make them the ideal partner in providing lasting solutions for your engine systems.

References

"Automotive Oil Separator Systems." Engine Builder, 2021.

"Oil Separator Technology and Application." Journal of Industrial Applications, 2019.

"Crankcase Ventilation and Oil Separator Functionality." Automotive Engineering Journal, 2020.

Please visit product page for more information

-

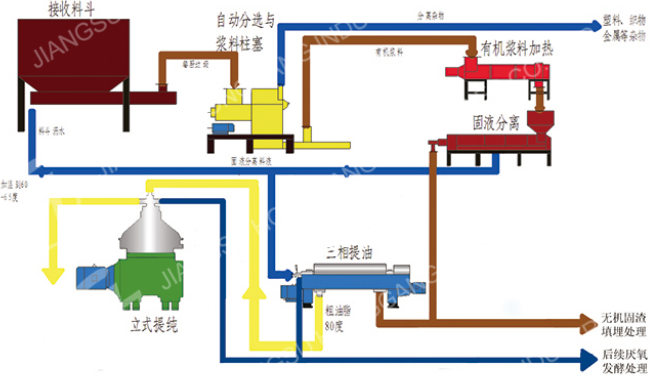

Separator for kitchen Waste Oil and Illegal Cooking Oil

Huge amount of Kitchen waste oil or illegal cooking oil (commonly known as slops, swill, pigwash) can be treated and obtain biogas, biodiesel, organic fertilizer, high- protein feed and other products. However the mature technical support is necessary to support the oil-water-solid separation in this treatment processing, our technical engineers with their advanced design concept have been researched and developed the new special disk separator based on its hard separation feature of Kitchen waste oil or illegal, and make the separation efficiency reaches to the extreme and suoer conditions.

More