Product recommendation

How a High-Speed Soap Cutting Machine Can Boost Your Productivity

In the competitive landscape of soap manufacturing, production efficiency, cutting precision, and hygiene compliance are more critical than ever. As demand grows for high-quality bar soaps in both consumer and industrial markets, soap manufacturers must invest in advanced technologies that increase speed without sacrificing product quality.

At JIANGSU SOHO HONRY WUXI CO., LTD., we understand these challenges and have engineered the solution: a high-speed soap cutting machine designed to dramatically enhance your productivity while delivering unmatched cutting accuracy and production consistency.

Why Speed and Precision Matter in Soap Production

In soap production lines, the cutting stage is one of the most essential and time-sensitive processes. After the soap passes through the plodder and is extruded into continuous bars, it needs to be cut into uniform pieces at high speed. Inaccurate or inconsistent cutting can lead to product waste, packaging issues, and reduced customer satisfaction.

A precise cutting machine for soap production not only improves the appearance and consistency of soap bars but also ensures compatibility with downstream packaging systems. When speed and precision are combined, the result is higher output, fewer rejects, and better overall profitability.

Built for Speed: 300 Cuts Per Minute

Our high-speed soap cutting machine operates at an impressive speed of 300 cuts per minute, allowing your production line to process a significant volume of soap billets in a very short time. Whether you're cutting soap billets for toilet soap or processing embossed laundry soap bars, this machine handles the workload with ease, significantly increasing output and reducing downtime.

This high-speed functionality is perfectly synchronized with the soap plodder, ensuring a smooth, uninterrupted workflow. The synchronization capability means the cutting speed automatically adjusts to match the plodder speed, preventing overfeeding, jamming, or waste.

Precision at the Core: Adjustable Cutting Length and Thickness

As a precise cutting machine for soap production, one of the most powerful features of the SOHO HONRY high-speed soap cutting machine is its precision cutting capability. With adjustable length settings (from 50mm to 999mm) and cutting thickness ranging from 5mm to 70mm, manufacturers can produce a wide variety of soap sizes tailored to market needs or customer requirements.

The cutting length can be freely set via a touch screen interface, providing user-friendly operation and total control. This level of customization ensures you maintain consistency in product size and shape, a key factor in brand reliability and consumer satisfaction.

Dual Functionality: Cutting and Embossing

For laundry soap production, our machine offers an optional embossing mechanism at the cutting head. This means the machine not only cuts but also embosses the soap bars with branding or pattern elements in one seamless operation. This dual function simplifies the production process, reduces the need for additional machinery, and cuts down on production time and space.

Industrial-Grade Quality and Control

SOHO HONRY’s high-speed cutting machine is equipped with international brand industrial control systems, guaranteeing durability, safety, and stable performance over long-term usage. Built with high-quality materials and components, this machine offers long operational life with minimal maintenance needs.

The design is compact, efficient, and tailored to industrial environments — making it suitable for both small-scale factories and large-scale production facilities.

Energy-Efficient and Cost-Saving

With a power consumption of only 3.5 kW, the machine is highly energy-efficient without compromising performance. This reduces operational costs significantly over time and supports manufacturers in meeting environmental and sustainability goals.

In addition to power efficiency, the high-speed cutting reduces material waste, labor costs, and machine idle time — all contributing to a higher return on investment (ROI).

Key Features of SOHO HONRY’s High-Speed Soap Cutting Machine

Our high-speed soap cutting machine incorporates advanced automation and smart engineering to handle continuous soap production environments. Here are the core features that make our machine stand out:

1. Revolving Code for Online Sensing and Synchronization

The machine uses an intelligent revolving encoder to automatically sense the movement of the extruded soap bar. This enables real-time synchronization of the cutting blade with the soap’s extrusion speed, ensuring a clean, accurate cut every time.

2. Adjustable Cutting Speed to Match the Plodder Output

Soap extrusion speeds can vary depending on product type, shape, or material. Our machine allows users to easily adjust the cutting speed so that it perfectly matches the speed of the soap plodder. This eliminates lag, misalignment, or uneven cuts during high-volume production.

3. Touchscreen Control Panel for Length Setting

Operators can set the exact length of each soap bar directly on the integrated touchscreen interface. This precise control allows for quick adjustments during production and supports a wide range of bar sizes without mechanical changes or downtime.

4. Stable Frame and Durable Blade Mechanism

The cutting mechanism is designed with industrial-grade materials that ensure minimal vibration and maximum durability. The stainless-steel blade is sharp, wear-resistant, and easy to replace, which contributes to minimal maintenance requirements and long service life.

Applications of Our High-Speed Soap Cutting Machine

● Toilet Soap Billet Cutting: Perfectly cut billets ready for stamping

● Laundry Soap Bar Embossing & Cutting: Emboss and cut in a single operation

● Custom Soap Sizes: Adjustable length and thickness for various product requirements

● Mass Production Lines: High-speed capacity ideal for large-scale manufacturing

● High-End Product Finishing: Precise cutting for premium soap shapes and sizes

Why Choose SOHO HONRY?

JIANGSU SOHO HONRY WUXI CO., LTD. has built a reputation as a reliable manufacturer of advanced soap production equipment. Our focus on automation, precision, and durability enables us to deliver machines that meet the evolving needs of the global hygiene and personal care industry.

When you partner with us, you benefit from:

● Decades of engineering expertise

● Tailored solutions for your production line

● Competitive pricing and fast delivery

● Ongoing technical support and after-sales service

We don’t just sell machines—we build partnerships that help your business thrive.

Get in Touch and Boost Your Output

If you're looking for a high-speed soap cutting machine that combines speed, precision, and durability, look no further than SOHO HONRY. Let us help you modernize your production line and take your soap business to the next level.

Contact us today to learn more, get a customized quote.

Please visit product page for more information

-

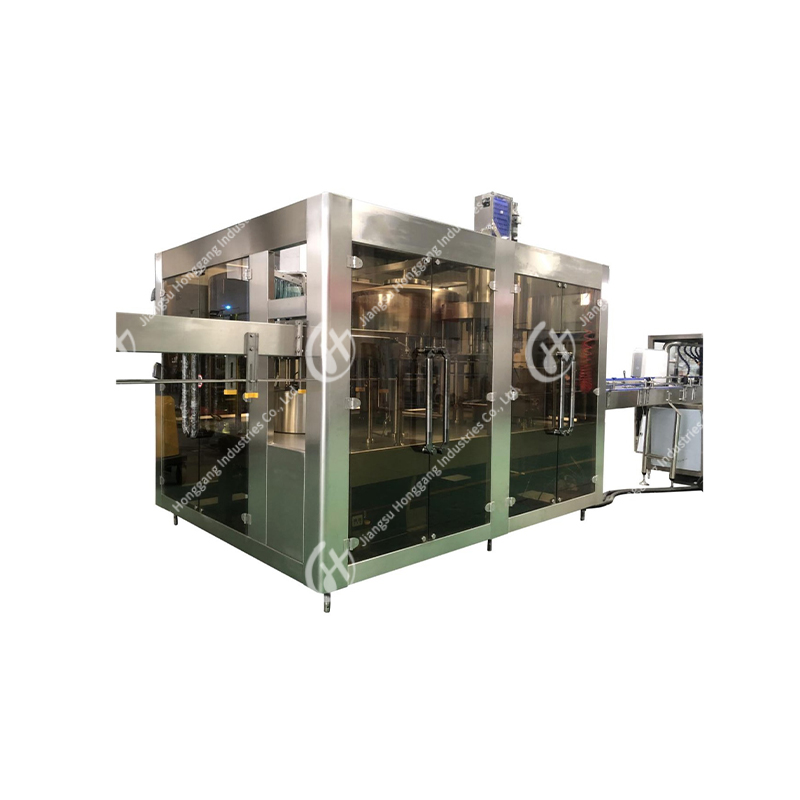

Cutting Machine

It adopts revolving code for online testing and cutting speed needs to be adjusted to be same a plodder all the time. It can set the length freely by setting in the touch screen. International brand industrial control and have high quality.

More