Product recommendation

How does an oil refinery work: A scientific journey from crude oil to finished oil

Oil Refinery is an indispensable part of the oil industry, which converts crude oil extracted from the ground into finished oil such as gasoline and diesel used in our daily lives. In this article, we will explore in detail how does an oil refinery work, from the processing of crude oil to the production process of the final product, revealing the science and technology behind it.

How does an oil refinery work?

Crude oil processing and preliminary separation

1. Storage and preliminary processing of crude oil

Oil Refinery first receives crude oil shipped from the oil field, which usually contains impurities and water. Through a series of pretreatment processes such as dehydration, desalting and degassing, the crude oil is initially purified. This not only protects subsequent equipment, but also ensures the efficiency of subsequent processing.

2. Preliminary fractionation

The crude oil after preliminary purification enters the fractionation tower, and the crude oil is divided into different fractions by heating and fractionation. These fractions include light petroleum products such as gasoline and liquefied petroleum gas, as well as heavy petroleum products such as fuel oil and lubricating oil.

Chemical conversion process

1. Catalytic cracking

Catalytic cracking is the key process for converting heavy fractions into light fractions. Through the action of catalysts, large molecular hydrocarbons are cracked into small molecular hydrocarbons, increasing the output of gasoline and diesel. This process not only improves the quality of fuel, but also increases the economic benefits of oil refinery.

2. Hydrotreating

Hydrotreating is mainly used to remove harmful substances such as sulfur and nitrogen from crude oil and fractions, and can saturate olefins, improve the stability and combustion performance of fuel. This is not only a need for environmental protection, but also an important step to improve fuel quality.

Refining and finished oil production

1. Refining process

The products after chemical conversion need to be further refined. The refining process includes steps such as re-fractionation, hydrorefining, and desulfurization to ensure that the products meet strict quality standards. For example, hydrorefining can remove excess sulfides and reduce sulfur dioxide emissions in tail gas.

2. Blending of finished oil

Finally, the blending of finished oil is a delicate process. Different fractions are mixed in strict proportions, and necessary additives such as antioxidants, detergents, etc. are added to ensure that the finished oil performs well in actual use.

How does an oil refinery work? This is a complex and delicate scientific process. From the initial treatment of crude oil to the final blending of finished oil, each step requires precise control and advanced technical support. This article introduces the various links of Oil Refinery in detail, showing the entire production chain from crude oil to finished oil, highlighting the important role of Oil Refinery in modern society. Through an in-depth discussion of how Oil Refinery works, we not only understand its technical details, but also recognize its key position in energy supply and environmental protection.

Please visit product page for more information

-

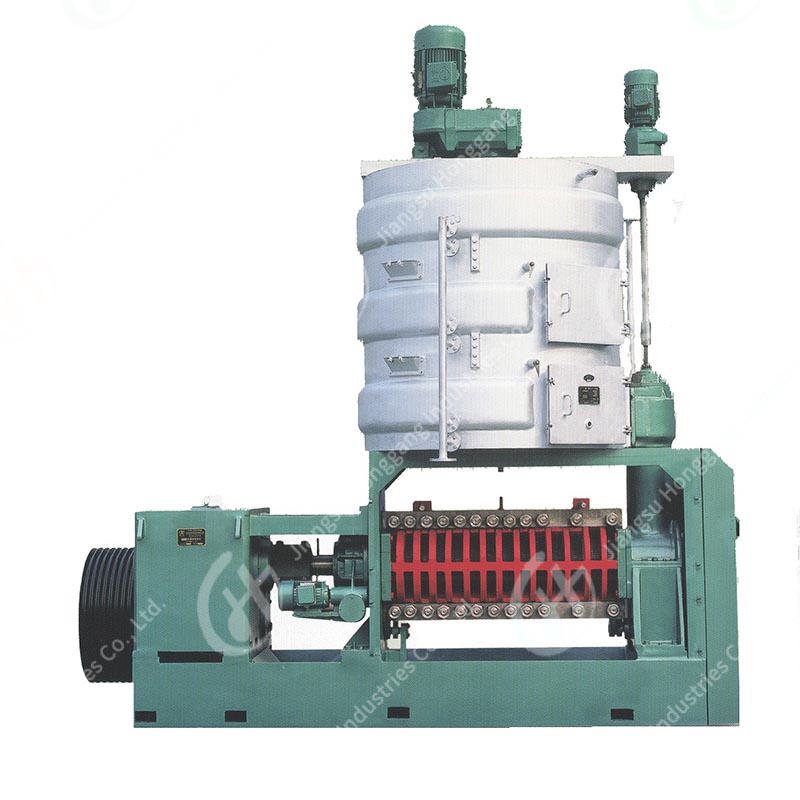

ZX28-DW Oil Press

√ Good wear resistance and long service life of wearing parts √ Lower oil in cake rate √ Forced feeding, increase capacity √ Strengthen the steam cooker structure and extend the service life

More