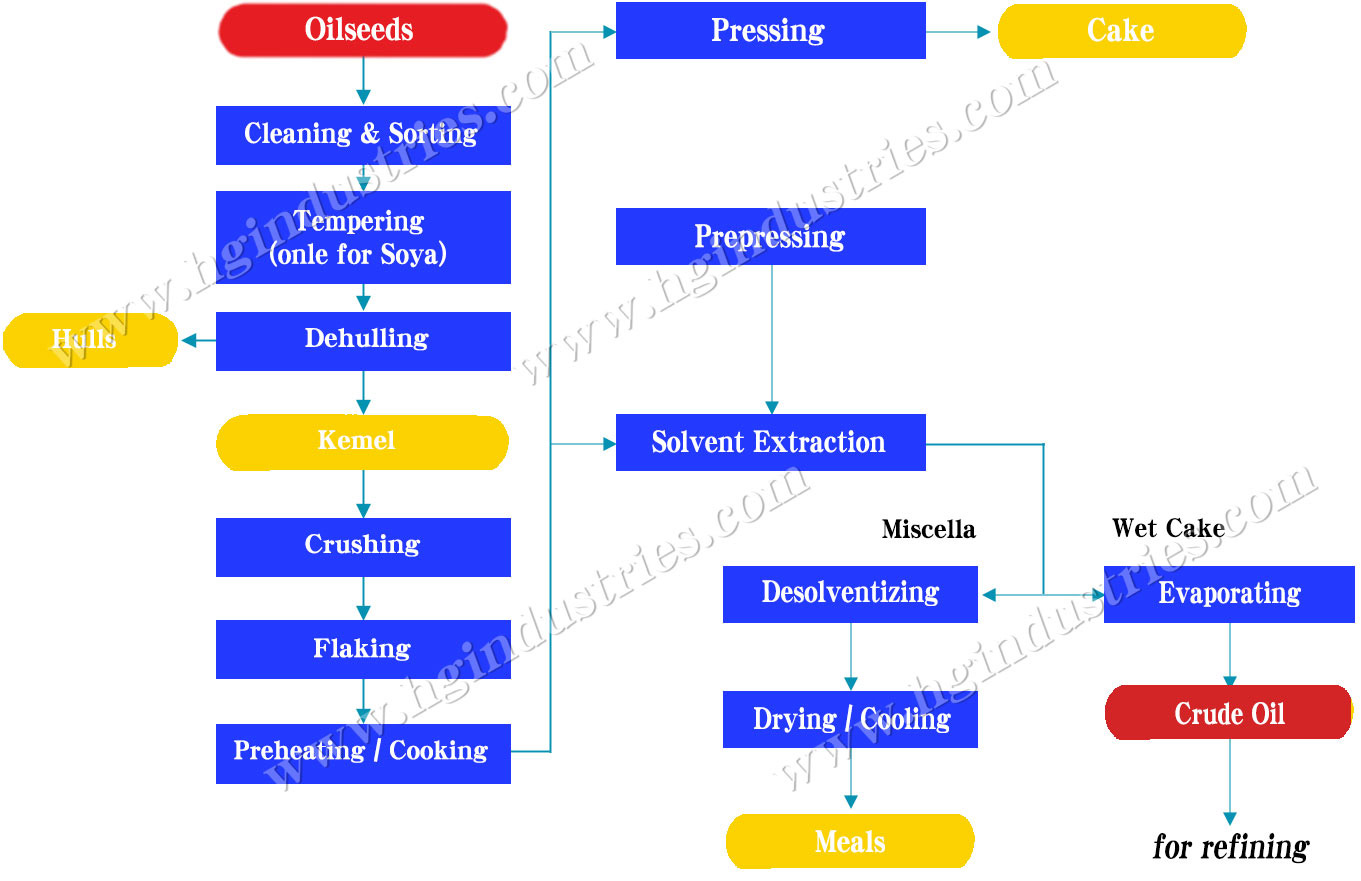

PRETREATMENT PROCESSING

The production of small varieties of oil is generally not high, and the pre-treatment section is basically the same as the pre-treatment section of conventional oil. It is generally cleaned by metering, vibrating screen, stone removal machine, and magnetic separator, and the cleaned oil enters the next section. However, processing plants often alternate processing of multiple raw materials based on market demand and different seasons of raw material production, with significant differences in size, shape, and bulk density. Therefore, the configuration of pre-treatment equipment should take into account multiple raw materials to meet production needs. For example, vibrating screens can be configured with various mesh shapes and specifications according to the size of different types of oil, so as to facilitate flexible application during production

Oil pretreatment and prepressing machine oil seed → cleaning →destorticating → shelling → crushing → flaking → cooking → oil pressing → refining → finished oil |  |

Cleaning

During the oil treatment process, one of the first steps is cleaning the raw materials, such as seeds or nuts, to remove any impurities or foreign matter. This is typically done using a combination of screening, aspiration, and magnetic separation techniques.

Dehulling

Some types of seeds or nuts, such as sunflower seeds or soybeans, have an outer hull that needs to be removed before oil extraction can take place. Dehulling can be done using a mechanical process, such as cracking the hulls with rollers or impacting them with knives, or by treating them with chemicals.

Crushing & Flaking

After the raw material has been cleaned and dehulled, the next step is usually to flake it. Flaking involves reducing the thickness of the material through a rolling process, which increases the surface area and makes it easier to extract the oil. Flaking may also help to break down cellular structures in the material, which can improve oil yield.

Cooking

Some oilseeds, such as soybeans, need to be cooked before they can be pressed to extract oil. Cooking helps to loosen the cellular structure and break down unwanted enzymes and proteins. This can be done using a variety of methods, including steam heat, hot water treatment, or roasting.

Extruding / Puffing(optional)

Through extrusion (puffing) by means of expander (extruder), the oilseeds materials will be expanded because of sudden pressure-relief, Meanwhile steam in the material is evaporated all of a sudden, so the material become microporous structure and expanded to irregular particles.