- Home

- >

- Solutions

- >

- Oil Mill Plant

- >

- Oil Press

OIL PRESSING

In order to meet the needs of different consumers and respond to market changes, according to the quality of raw materials, the oil pressing section can set up two processes: conventional oil pressing and cold pressing. Some products that need to ensure a strong aroma need to adopt conventional oil pressing technology, such as pumpkin seed oil, sesame oil, etc. A small variety of oil rich in multi unsaturated fat acids and trace active ingredients. In order to prevent oxidative deterioration, cold pressing process is adopted.

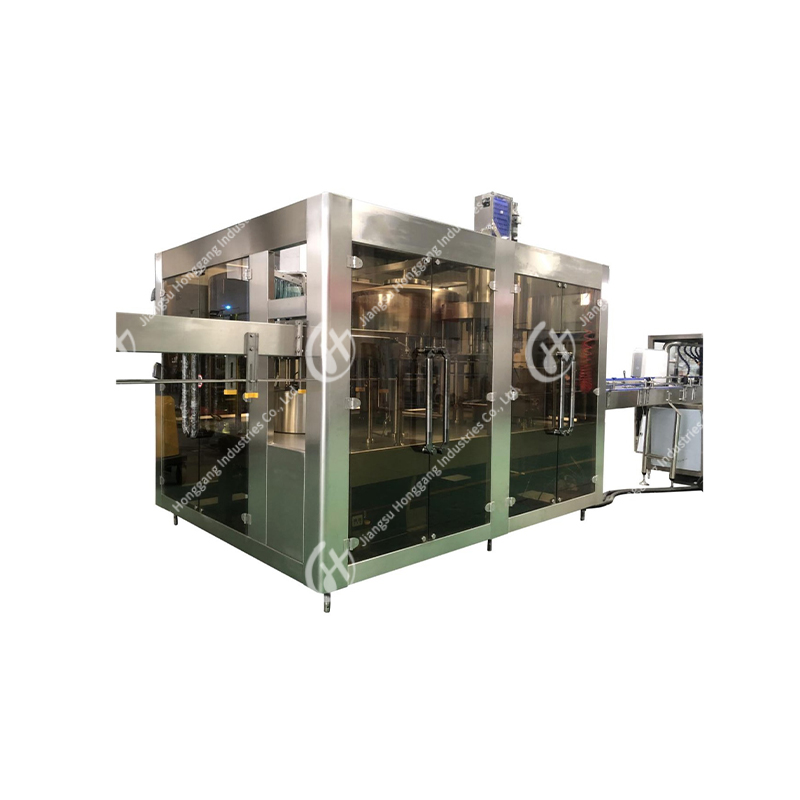

There are five kinds of cooking oil pressing machine usually used, single-screw oil press machine, with auxiliary frying pan oil press machine, with strainer oil press machine, hydraulic oil press machine and double-screw cooking oil pressing machine.

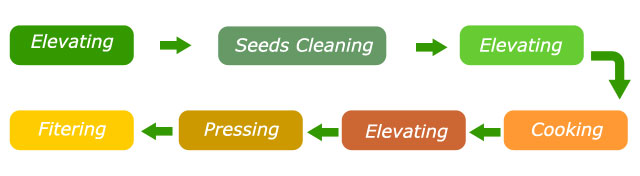

Oil Pressing Flowchart

Oil seeds preparation/pressing

Cooking oil is daily necessity for diet and human health. Oil seed preparation is to clean and prepare seeds into a condition suitable for mechanical pressing. The seeds can be groundnut (peanut), palm nut, sesame, sunflower seeds, cotton seeds, soybean, canola, maize germ, etc. The preparation usually involves cleaning, crushing/decorticating, flaking, cooking before feeding into press.

The key equipment is oil press/expeller. We have big range of capacity from 50t/d to 300t/d feedstock pre-press and 5t/d to 150t/d full press.

Technical details

Capacity | 5T/D-1000T/D |

| Seeds | peanut, palm, sesame, sunflower seeds, cotton seeds, soybean, canola, maize germ |

| Work Flow | Silo->Cleaner->Dehusker->Kenel & Shell Separator->Cooker->Oil Press |

Soybean Oil Pressing -- |

|

| Sunflower Seeds Oil Pressing -- |

Peanut Oil Pressing -- |

|

| Sesame Oil Pressing -- |

Corn Oil Pressing -- |

|

| Castor Oil Pressing -- |

Canola Oil pressing -- |

|

| Cottonseed Oil Pressing -- |

Mechanical Oil Pressing Types

● Single Pressing (Full Pressing):

Single pressing is a process whereby oil seeds are only pressed one time using an oil press. The oil yield from this process is usually lower compared to other methods. However, the oil produced through single pressing is often of high quality and purity.

● Pre-pressing:

Pre-pressing is a technique used where oilseeds are subjected to a preliminary pressing to remove some of the oil content, leaving behind a cake that can be further processed to extract the remaining oil. The resulting oil from pre-pressing is usually of good quality and has a higher yield.

● Hot Pressing:

Hot pressing is another oil pressing method that involves heating the oilseeds before the pressing process. This method results in a higher oil yield but can also lead to a lower quality of the oil.

● Cold Pressing:

Cold pressing is a method that involves pressing oilseeds without any added heat or chemicals. This method produces oil that retains more of its natural flavor and nutrition. However, the yield of oil from cold pressing is usually lower compared to other methods.