GRAIN CLEANING & HULLING

Main Methods of Grain Cleaning Plant

Screening (different size): Remove impurities which are larger or smaller than wheat or other grain by sieving machine.

Air Separation (different floating velocity in air flow): Remove light impurities by air separator.

Gravity Grading (different specific gravity): Remove the inorganic impurity (stones and mud)having similar size but different specific gravity by specific-gravity stoner.

Magnetic Separation(Different magnetism): Remove magnetic metals by magnetic selector.

Fine Selecting (different shapes): Remove round impurities which are shorter or longer than wheat by foreign seeds extractor.

Impacting (different strength): Crush the impurities with lower strength than wheat by wheat scourer, thus screen out these impurities.

Optical Analysis (different color): Remove impurities having different color with wheat by color selector.

Hulling / Peeling: Remove the peels of grain such as wheat, corn, sorghum and beans (Soybean, black soya bean, broad bean, butter bean, kidney bean, navy bean, mung bean, small red bean, sword bean, pea, pigeon pea, cowpea, phaseolus coccineus, chickpea, lentil…)

Bean Cleaning Sorting Processin

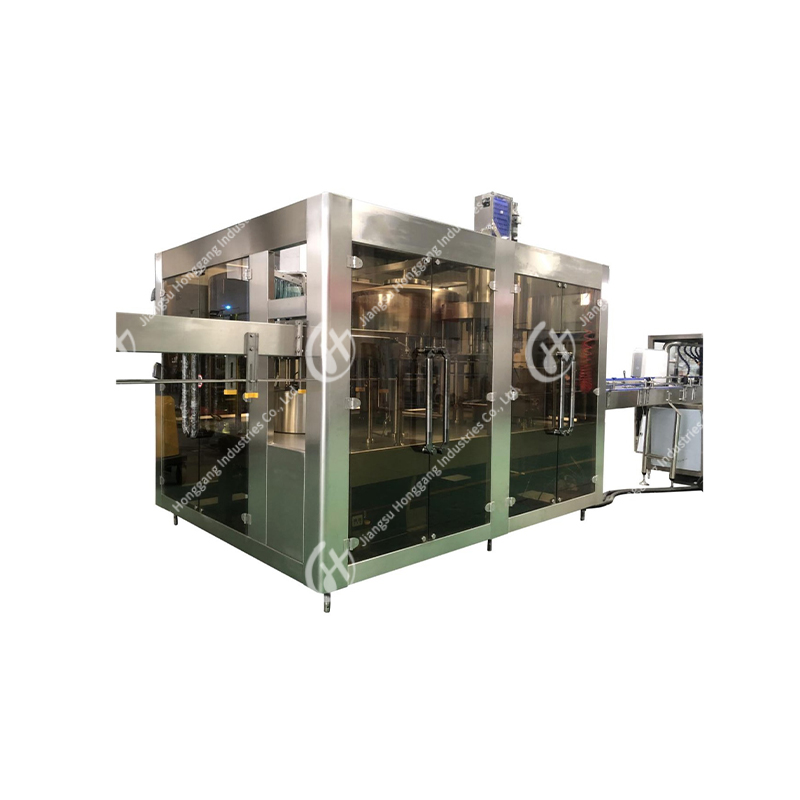

The complete bean cleaning and selection equipment can be applied to the cleaning, selection and polishing of various beans such as soybeans, mung beans, peas, red beans, and coffee beans. Overall coverage: vibrating grain cleaning, specific gravity stone removal, magnetic soil removal, secondary selection, polishing and brightening, photoelectric color sorting, grading and packaging, etc. The conveying equipment adopts anti-breaking lifting and conveying equipment to reduce the loss of grain processing.

Grain vibration cleaning→specific gravity stone removal→magnetic soil separator→twice sorting→polishing and brightening→optical color sorting→grading and packaging

REMOVING LARGE AND SMALL IMOURITIES The raw grain is conveyed to the high-efficiency vibrating screen by the grain elevator, thus cleaning and removing the impurities in the raw grain. |  |

| REMOVING THE LIGHT IMPURITIES Equipped with a vertical suction duct to remove light impurities in the raw grain, such as pods, leaves, weeds, etc. |

REMOVING THE DIFFERENT SIZE STONES The raw beans processed by the high-efficiency vibrating screen enters the gravity grading destoner to remove stones with different size. |  |

| MAGNETIC SEPARATION The magnetic separator is added this part to remove the mixed magnetic substances and sand in beans, so as to obtain pure raw grains. |

SOILS CLODS SEOARATION After the raw grains have been cleaned and destoned, some soil clods are similar in bulk density and size to beans, so a magnetic soil separator is used to separate mixed soil other magnetic minerals. |  |

| SELECTING OUT SHRIVELED AND MOLDY GRAINS The specific gravity separator is equipped here to separate the materials with different specific gravity, like shriveled grains and mildewed grains to achieve the purpose of cleaning. |

POLISHING Through the internal special structure of the bean polishing machine, the beans are brushed to make the surface bright. |  |

| COLOR SORTING The polished beans enter the optical sorter. Application of technology of Industrial color CCD and HD image acquisition helps select out different-colored beans. |

GRADING We have designed special grading machines for beans and pulses classify the beans by size and separate them into different grades, which provides an even distribution of product. |  |

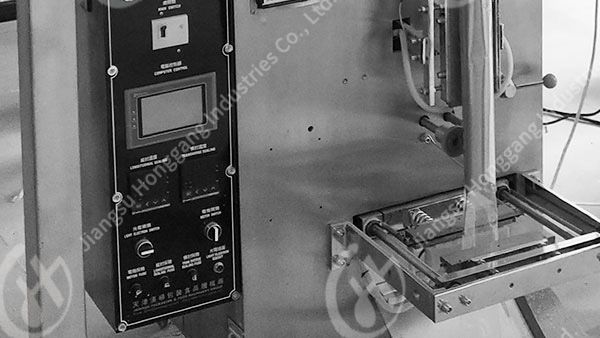

| FINISHED PRODUCT BAGGING The graded finished beans are conveyed to the packaging section. We offer a wide range of manual and fully automated weighing and bagging systems. |