Press

-

![Steam Cooker]()

Steam Cooker

√ Standard reducer √ Improve flaking quality in order to increase oil output rate and the quality of crude oil √ Also can be used as soften cooker

Learn more -

![160-180 t/d Screw Oil Press]()

160-180 t/d Screw Oil Press

√ Large capacity, lower oil in cake rate √ Standard gearbox, independent main bearing box √ Reasonable structure design √ Integral seal, stainless steel shields

Learn more -

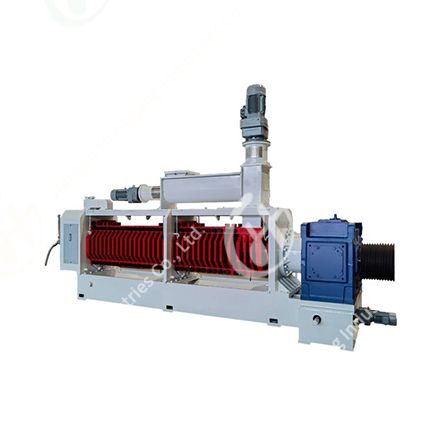

![500-650 t/d Screw Oil Press]()

500-650 t/d Screw Oil Press

√ With forced feeding system, large capacity √ Lower oil in cake rate √ Stable structure, convenient operation and maintenance √ Good sealing, with odor substance outlet

Learn more

Mass Storage Tank

Bearing

-

![Water Pump Bearing]()

Water Pump Bearing

Our Water Pump Bearing is engineered to deliver exceptional performance and reliability in automotive water pump applications. Designed for longevity, it is built with premium materials to withstand extreme temperatures and harsh environments, ensuring a smooth and efficient operation of the water pump system. This Water Pump Bearing is compatible with a wide range of vehicles, including cars, trucks, and commercial vehicles. Whether you’re replacing a worn-out bearing or upgrading your water pump system, our bearing provides the durability and reliability you need for peace of mind on the road.

Learn more -

![Wheel Hub Bearings DU/DAC]()

Wheel Hub Bearings DU/DAC

Our Wheel Hub Bearing is meticulously engineered to ensure the smooth and safe operation of your vehicle’s wheels. Designed to withstand the rigors of daily driving, this bearing is made from high-quality materials that offer exceptional durability and performance. Whether you’re driving on the highway or navigating rough terrain, our wheel hub bearing provides the stability and reliability you need for a comfortable ride. Designed to fit seamlessly with most vehicle models, our wheel hub bearing allows for quick and easy installation, reducing downtime.

Learn more -

![Deep Groove Ball bearings of 6000/6200/6300/6400/6800/6900/16000/ Series]()

Deep Groove Ball bearings of 6000/6200/6300/6400/6800/6900/16000/ Series

Deep Groove Ball Bearings are engineered to support high radial and axial loads, providing robust performance even under demanding conditions. The design of these bearings ensures minimal friction, leading to smoother and quieter operation. This feature is particularly beneficial in applications where noise reduction is critical. Made from high-quality steel, these bearings offer excellent resistance to wear and tear, ensuring long service life and reduced maintenance costs.

Learn more

Water Filling Machine

-

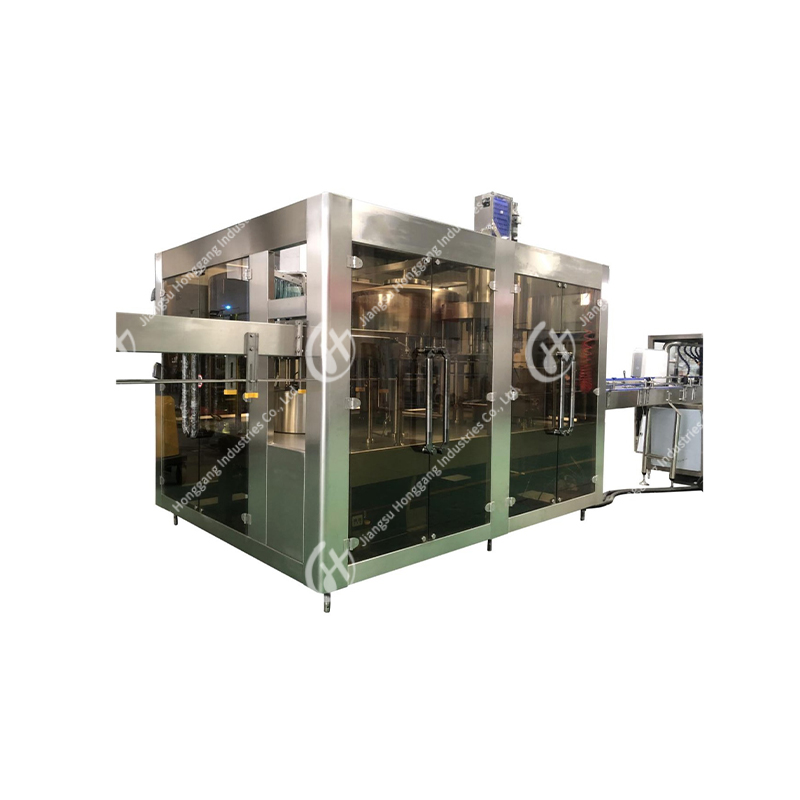

![Bottled water filling machine]()

Bottled water filling machine

1、Mainly used for (PET) polyester bottles of all kinds of mineral water, pure water, mountain spring water, wine and other gas-free drinks production. 2、Wash, fill, and cover on one machine. 3、Shorten the contact time between materials and the outside world, and improve the sanitary conditions, production capacity and economic benefits. 4、 Hanging card bottle mouth conveying bottle structure, replace the bottle type more convenient, fast. 5、The host adopts advanced PLC programmable automatic control technology. 6、The key electrical appliances are made by Siemens, Mitsubishi, Schneider, Omron and other well-known products.

Learn more -

![Bubble wine, champagne wine production line]()

Bubble wine, champagne wine production line

1、The high-precision mechanical filling valve has the characteristics of no bottle and no vacuum extraction. 2、Open gear junction and gear transmission, with a clutch device, frequency conversion speed regulation equipment expands the speed modulation range. 3、With the automatic lubrication device, the lubrication point can regularly lubricate the machinery, high efficiency, low noise, long life. 4、Parts of the machinery can be adjusted to fit the different types of bottles 5、The electronic probe controls the level of the level in the bottle to make the level more accurate. 6、The key appliances are Siemens, Mitsubishi, Schneider, Omron and other well-known products.

Learn more -

![Disposable barrelled water filling machine]()

Disposable barrelled water filling machine

1.The 5-15 L bottled water production line is exclusively used for 5-15 L bottled water production. 2.Washing, filling and capping are achieved on one machine. 3. The bottle washing machine uses multiple washing liquid injection and disinfectant injection to achieve the purpose of washing and disinfection, and the disinfectant can be recycled. 4. The seal can seal automatically to ensure that the cap is sterile and clean. 5. The production line has compact structure, small area and high degree of automation. 6. The key appliances are Siemens, Mitsubishi, Schneider, Omron and other well-known products.

Learn more