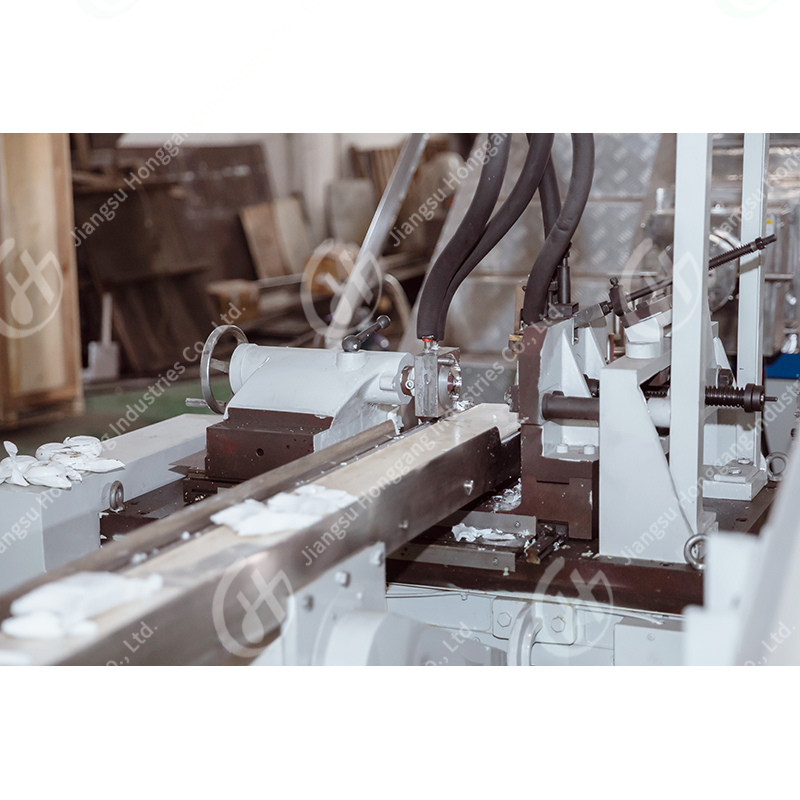

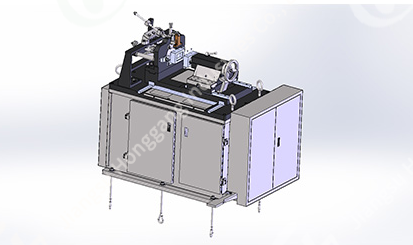

Stampping Machine

This equipment was improved form XG 01 which was widely used in domestic market. The stamping part used crank connecting rod mechanism instead of cam transmission to eliminate vibration and noise in order to enhance production efficiency and life time. This equipment can be matched with SDJ Duplex Vacuum Plodder to form continuous automatic production line and to meet technique requests of soap moulding.

Details

Main Features:

This equipment was improved form XG 01 which was widely used in domestic market. The stamping part used crank connecting rod mechanism instead of cam transmission to eliminate vibration and noise in order to enhance production efficiency and life time. This equipment can be matched with SDJ Duplex Vacuum Plodder to form continuous automatic production line and to meet technique requests of soap moulding.

Main Technical Data:

| Type: | Electromagnetic Speed Regulation, reciprocating straight line, long bar stamping. |

| Capacity: | 80 - 120pcs/min |

| Weight Of Soap: | 50 - 250g |

| Reciprocating Stroke: | 115mm |

| Power Consumption: | YCT - 160 - 4B 3Kw 115 - 1150rpm |

| Overall Dimensions: | (LxWxH) 3560x1410x1135 |

| Gross Weight: | 1950Kg |

Working Principle

Connecting with soap plodder, the soap billet is conveyed through conveyor to stamper.After stamping, the soaps are collected by hand.